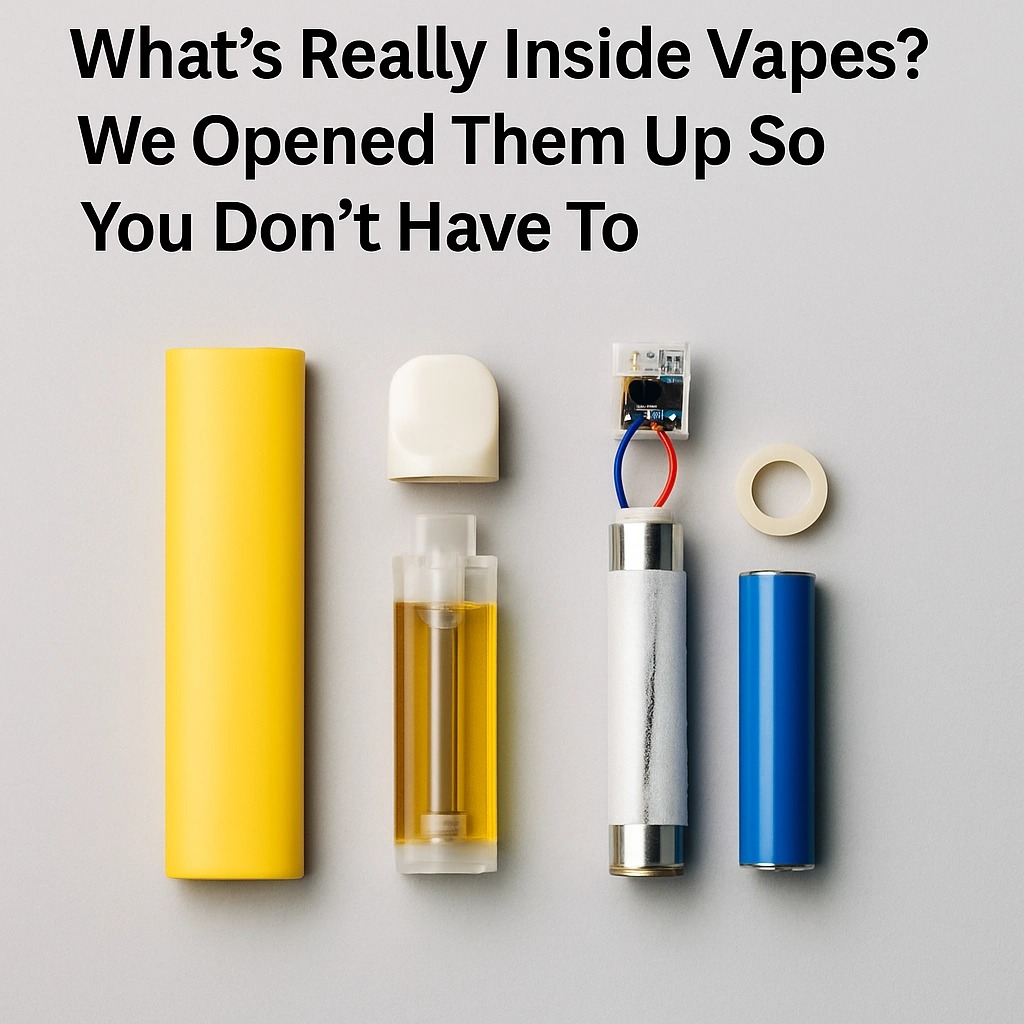

Walk into any convenience store or vape shop today and you’ll see an entire wall of disposable vapes—bright colors, long puff counts, bold flavors. They look simple on the outside, but the inside tells a much bigger story. Whether you’re a retailer, distributor, or building your own private-label line, understanding the internal components of modern vape devices is more than curiosity. It’s a key part of choosing reliable suppliers, avoiding failed batches, and protecting your brand reputation.

So we did what every curious B2B buyer wishes someone would do: we pulled vapes apart, studied the structure, and compared what’s inside to the promises on the box.

This is a deep look into the anatomy of disposable vapes and pod systems—and what quality really looks like under the shell.

What’s Actually Inside a Modern Vape?

At first glance, most disposable vapes look like simple plastic tubes. But once opened, you’ll find a surprisingly organized set of components working together to deliver vapor smoothly and consistently.

The Battery: The Heart of the Device

A vape’s battery is more than just a power source. Its stability determines everything—from flavor consistency to how fully the e-liquid gets used.

Inside most devices, you’ll find:

- Lithium-ion batteries ranging from 320mAh to 1100mAh

- USB-C charging ports (for rechargeable disposables)

- Built-in protection against overcharge or short-circuit

A weak or unstable battery leads to burnt taste, premature device death, and wasted e-liquid. High-quality devices avoid this problem by using safer cells and performance testing.

The Coil or Heating System

This is where flavor is created. Well-built devices typically use:

- Mesh coils for even heating

- Upgraded heating materials that avoid burnt hits

- Consistent temperature control

When we cracked open poorly made vapes, the coil often looked uneven or burnt—an instant red flag. High-grade devices showed clean mesh patterns and neat cotton placement.

The E-liquid Tank or Chamber

Depending on the design, you’ll see:

- Transparent or semi-transparent tanks for easy viewing

- Capacities ranging from 2ml to 25ml

- Leak-resistant seals and improved structural support

One thing that stood out in higher-end devices: the engineering around leak protection. Multiple layers, better seals, and precise molding made a massive difference. Cheap devices often used thin plastic and minimal sealing—exactly the kind that leaks in shipping or storage.

The Mouthpiece and Airflow System

A surprising amount of engineering goes into the airflow path:

- Designed channels that direct air smoothly over the coil

- Replaceable filter-style mouthpieces (common in more premium lines)

- Ergonomic shapes to match different vaping styles

The airflow structure has a huge impact on vapor thickness and flavor intensity. Poor airflow creates turbulence, reduces vapor, and makes flavors feel muted.

Control Chip, Sensors, and Safety Systems

Inside modern devices you’ll typically find:

- Draw-activation sensors

- Micro chips that regulate power output

- Safety systems for overheating or short-circuits

Well-designed devices contain clean, organized circuitry. Poor ones look messy—with wires crossing awkwardly and components glued in place.

Why These Internal Details Matter for Retailers & Distributors

Product consistency protects your brand reputation

A single defective batch can ruin a retailer’s long-term trust. Internal engineering determines:

- Burnt taste vs. smooth vapor

- Leaking vs. clean storage

- Full flavor output vs. muted hits

Good internals create predictable performance—and predictable performance keeps customers coming back.

Better structure = fewer after-sales issues

Distributors often face:

- Puff count complaints

- Battery failure

- Tank leakage

- Inconsistent flavor reports

Most of these issues trace back to poor internal structure. A better-built device leads directly to fewer headaches and fewer refund claims.

Internal design affects compliance and certification

Many markets already require testing for:

- Heavy metals

- Battery safety

- Emissions

- Material quality

Devices with clean internal structure pass certification more easily, reducing risk for brands operating internationally.

Disposable Vapes vs. Pod Systems: What’s Inside Each?

Disposable Devices

When opened, a good disposable device shows:

- Compact battery

- High-density cotton or tank

- Mesh heating element

- Clean wiring

- Tight seals

- Reinforced airflow channel

Disposable devices prioritize convenience: no refilling, no coil changes, no mess. They’re ideal for high-volume markets and quick turnover.

Rechargeable Pod Systems

Crack open a pod system and you’ll see:

- Replaceable pod cartridges

- More advanced chips

- Higher-quality battery cells

- Better mouthpiece engineering

Pod systems are designed for long-term use, making them popular among vapers wanting consistency and customization.

What We Learned After Opening Hundreds of Devices

After taking apart a broad range of disposables and pod systems, a few patterns became obvious:

Mesh coils outperform traditional coils in every category

Better flavor, smoother inhale, fewer burnt hits.

USB-C rechargeable disposables dramatically reduce e-liquid waste

Non-rechargeables often die with liquid still inside.

Multi-layer leak protection is a must for wholesale orders

Especially when shipping across hot climates.

Flavor consistency depends on the quality of internal cotton and its placement

You’d be surprised how often this is overlooked.

Devices with better airflow channels feel more premium

Good airflow = good customer experience.

If you’re choosing suppliers, these internal engineering details matter more than packaging or puff count claims.

Inside the Craftsmanship of Shenzhen Vapehome Technology Co., Ltd

Behind the AGAIN brand is a manufacturer with real engineering depth. Shenzhen Vapehome Technology Co., Ltd has been developing vape products since 2013, with strong capabilities in:

- Disposable vape R&D

- OEM/ODM services

- Full production and quality control

- Global compliance support

Their engineering stands out because they combine:

- Rigorous raw material selection

- Standardized manufacturing

- 100% in-line and final testing

- Product traceability

- Third-party lab checks for major markets

They also maintain strict confidentiality for OEM partners, offering patent-protected designs, flavor development, and packaging customization.

For buyers who want consistency—and need a partner that understands regulatory requirements—their structure and long-term reputation make them a reliable choice.

Conclusion

Most vapes look similar from the outside, but their internal structure is where the real story lives. Batteries, coils, tanks, airflow paths, chips, and even small seals work together to create the experience customers expect. For businesses buying wholesale or building private-label products, understanding what’s inside a vape is the difference between a successful product line and one that collapses under complaints.

And in a market where reliability matters, partnering with a manufacturer that treats internal engineering seriously isn’t optional—it’s essential.

FAQs

What’s really inside vapes, and why does it matter for wholesale buyers?

Inside vapes you’ll find a battery, coil, airflow system, tank, and control chip. These internal components determine flavor performance, longevity, and safety—key factors for distributors and retailers managing customer satisfaction.

Are disposable vapes different inside compared to pod systems?

Yes. Disposables have compact all-in-one structures, while pod systems include replaceable cartridges, more advanced chips, and stronger internal engineering designed for repeated use.

Why do some vapes leak while others don’t?

Leak resistance depends on tank material, sealing structure, cotton density, and internal pressure control. High-quality devices use reinforced seals and multi-layer protection to prevent leakage during transport.

How do mesh coils improve what’s inside vapes?

Mesh coils heat more evenly, reducing burnt hits and improving flavor delivery. They also last longer and perform more consistently across the lifespan of the device.

What should distributors check when choosing a vape manufacturer?

Look closely at internal engineering: battery quality, coil design, leak resistance, airflow structure, and testing procedures. These factors matter far more than packaging or puff count claims.